At the start of a race or track session we see drivers weaving back and forth across the track. Ask a driver why all the swerving and you’ll hear, "I’m getting the tires up to temperature." Well, I don’t think that’s what’s happening. Most of the tread surface is cooling, not heating. And, since rubber is a poor conductor of heat, very little of the frictional heating on the tread surface gets into the bulk of the tire.

Rubber is a very weird material. And a four-wheel vehicle with rubber tires, shock absorbers and a human driver is an extremely complex system. When it comes to tires it’s easy to grab on to a seemingly obvious explanation for what we see a tire doing only to find out it doesn’t really work that way. What we see is actually happening, of course, but the explanation we assign might not be correct. The sun, moon and stars seem to be rotating around our planet, but reality turns out to be more complicated. It took the invention of the telescope to reveal reality.

Tires Do Heat Up

Mainly, tires gain heat due to hysteresis-energy absorbed in the rubber when it is compressed, stretched or deflected in any way. Hysteresis is a characteristic of any viscoelastic material which certainly describes rubber. Visco says it’s viscous, elastic means it will stretch. Being viscoelastic, rubber stretches and bounces back, but not all the way back. Energy in not-all-the-way-back is lost in the rubber, but you never lose energy – in this case it becomes heat.

The thumbnail test (digging your thumbnail into the surface) reveals the level of hysteresis in a rubber compound. In any Club Racing paddock you’ll find a whole spectrum of tires: new, almost new and all used up. A driver once told me he preferred old tires because at the end of a track session they didn’t pick up rocks and dirt on the way to his paddock space!

Pressing a thumbnail into the tread rubber tells you two things. First you can tell how hard or soft the rubber is and, if you notice how quickly the rubber bounces back, you’ll get a reading on the level of hysteresis of that rubber compound. If the indention made by your thumbnail pops right back out you’ve found a low-hysteresis rubber, probably an old tire that’s endured quite a few heat cycles. A new race tire, especially a rain tire, will retain that indention for hours. We need hysteresis in rubber because it contributes to grip, but that’s another story.

Tread Temperature Variation

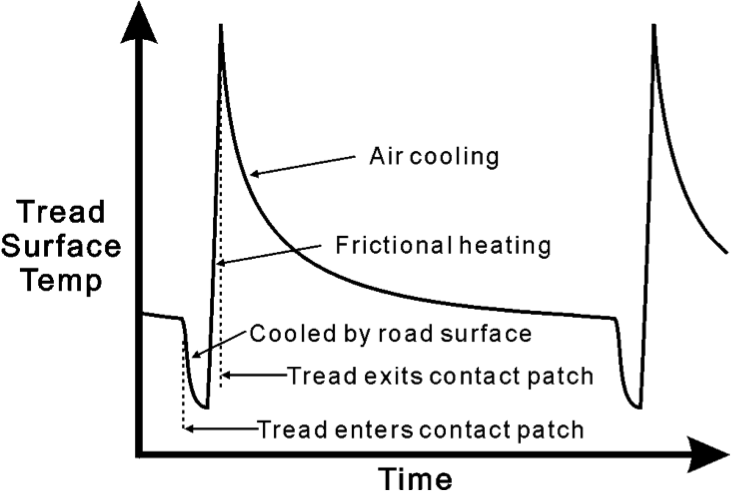

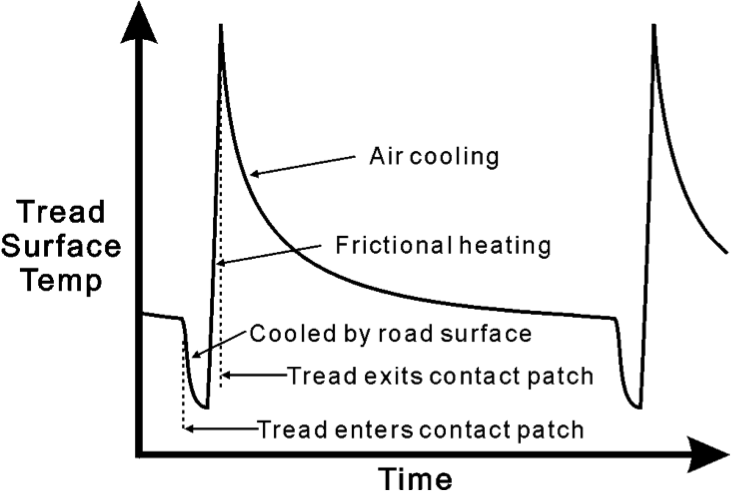

The graphic above shows that only a very small portion of the tread surface is heating at any one time. The black line traces the temperature of a spot (maybe only a few molecules thick) on the tread surface of a rolling race tire generating maximum grip in a corner. The vertical value of the graph is temperature increasing upward, and the horizontal value is time increasing to the right. This graph did not come from actual data because we don’t know how to measure instantaneous tread surface temperature in the contact patch. But data taken with infrared sensors mounted so they look at the tread on the back side of a tire can record temperatures over 350 deg F.

The solid line shows how surface temperature changes as a loaded tire rotates at speed and maximum grip. Our spot on the tread is in the contact patch during the time between the two dotted lines. We can see the rubber is air cooling as it comes into the contact patch and is cooled further by the road surface at the front of the contact patch where the tread is stuck to the road. Further back in the contact patch where sliding occurs, frictional heating quickly spikes the surface temperature way up, maybe as high as 400 deg F. But when the rubber comes out of the contact patch, it quickly cools, first by air rushing over the tread and then by the road surface as our tortured little rubber molecules once more enter the contact patch.

The observation here is that heating only occurs for a very small amount of time. Most of the time it takes for our molecules to rotate through one cycle they are cooling, not heating. And because rubber doesn’t allow easy passage of heat, what heat was generated at the surface didn’t get very far into the tread rubber.

How Much of the Tread Is Heating?

A tire 26 inches in diameter is about 82 inches in circumference. Inflated to 20 psi and loaded at 500 pounds gives us a contact patch area of 25 square inches. You can find a lot of race tires with tread widths between 6 and 16 inches so the loaded contact patch length is between 4 and 1 inches. That tells us our rubber molecule is in the contact patch for 2% to 4% of the time during one revolution. And, of course, it means that 96% to 98% of the tread surface is constantly cooling, as long as that surface is at a higher temperature than ambient air or the road surface.

The point here is very little of the tire is being heated – most of it is cooling.

Rubber Is an Insulator

Rubber is a good insulator so heat passes through rubber very slowly compared to other materials. For example the coefficient of thermal conductivity of rubber is 0.015 BTU/hr in deg F. That says that only 0.015 BTUs of heat passes through one inch of rubber per hour if the temperature difference is 1 degree F between the two surfaces of the 1 inch thick sample of rubber. This is about the same as polystyrene foam used as insulation in cold drink coolers. Steel has a thermal conductivity of about 300, that of aluminum is 1,000.

The insulating characteristics of rubber is why hysteresis heating in the plies has a tough time getting out of the tire and frictional heating at the tread surface can’t get in.

Is There Any Benefit from Swerving?

One of the people I spoke with on this subject was Arnaud Dufournier, President of Dufournier Technologies, a French company with some specialized tire testing hardware and software. Here’s what he had to say:

"We worked a few years ago on that subject for Formula 1, and the study we did showed that swerving increases tread temperature a small amount but really less than people think. Braking has a very low impact on tire heating because it doesn’t last long enough, one or two seconds. The best way to heat-up tires is to spin them, but it works only for rear tires and it’s possible to damage the tires.

"Swerving with quick movements of short duration do very little heating. Longer movements over a wider portion of the track work better but still don’t generate very much tire heating and the driver risks picking up dirt and rubber from the track and that degrades tire performance."

Better to Keep Going Straight

Probably the best thing a driver can do for the tires at the start of a race or track session is to alternately accelerate hard and brake hard while keeping the car going straight. This helps clean debris off the tread surface and warms the brakes. The tire will heat up just from rolling but could still take a couple of hard laps to come up to operating temperature. Really good drivers learn to go fast, but within the capability of the tires during those first few laps.

So, swerve if you want. But it’s not heating the tires!